Brief – Measuring Construction Vibration

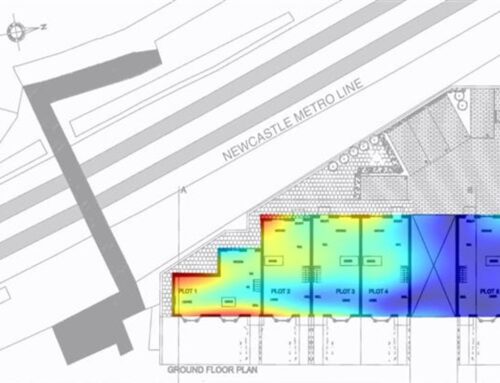

Graham Construction were constructing student accommodation on a plot next to a factory producing waterproof panels (Grant Westfield). Grant Westfield expressed concern that vibration caused by construction activities would affect the capabilities of one of their production machines.

Solution – Vibration Monitoring

Xi Engineering placed vibration sensors at key locations on Grant Westfield premises. This allowed the monitoring of vibration levels at the sensitive production machine, whilst determining whether any increase in vibration levels was due to Graham Construction’s construction activities or due to activity inside the production facility. Alarm levels were set which would notify Graham Construction when their work was causing undue vibration levels at the production machine.

Our Role

- Maintained and monitored the vibration sensors.

- Produced an installation report, weekly reports and an end of term report after the monitoring had ended.

- Expert advice and analysis on the recorded vibration sensor data.

The benefits of vibration monitoring

- Multiple vibration monitor approach allowed construction to continue unimpeded by false alarms caused by activity in the production facility.

- Vibration monitors could be remotely accessed and data analysed from any location

- Automatic alarm notifications sent to pre-determined email addresses.

Equipment & Software Used

Equipment:

Vibra+ Live PPV monitoring systems were used, supplied by ANV Measurement Systems. Captured vibration data is transmitted to the cloud and accessed on a web browser-based software. The equipment is robust and suited for deployment in a harsh production or construction environment.

Software:

- Livenviro – web browser-based vibration monitoring software.

- Matlab – used for further analysis of data.

Xi’s Role: Simulation and Analysis

Xi worked collaboratively with Arrayjet as an R&D partner to develop models in COMSOL Multiphysics using the Solid Mechanics and Computational Fluid Dynamics Modules to better understand microfluidic gasket sealing and fluid flow between the aspirator and printhead modules. Arrayjet provided expertise in device design and operation and Xi developed solid mechanics models to characterize the sealing of gaskets with a non-standard geometry as well as CFD models to study the flow of fluid along the entire fluid path between the open sample reservoir to the printhead and back during cleaning.

Client Benefits

- Independent vibration monitoring service.

- Immediate reporting of excessive vibration levels.

- Hands-on approach – Xi took responsibility for the maintenance and monitoring of the vibration sensors and liaised directly with the vibration-sensitive receptor.

- Advice for reducing the impact of construction vibration available.

- Thorough reporting.