Modelling Lithium Ion Batteries

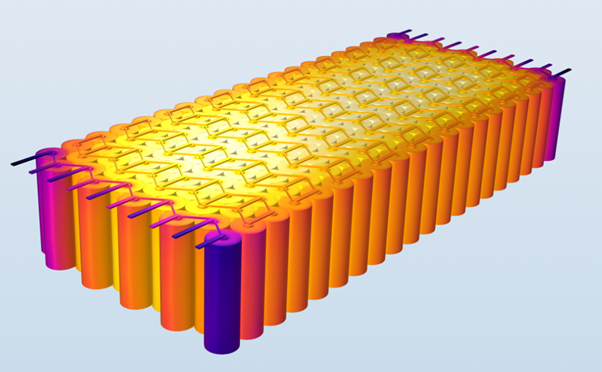

Batteries are extremely complex systems, and because of that there’s always room for improvement. Indeed, that’s why lithium-ion battery research and development is a massive ongoing endeavour. Factors include material usage, efficiency, safety, size and power. Therefore, with so much to study, simulation can help improve a development project and reduce its reliance on wasting materials in testing.

Innovating How We Power our Technologies

Since the beginning of time, people have continuously developed and improved the ways they transport themselves and their goods, allowing groups to travel and settle in new locations and open up new opportunities. Today, we are in the midst of another transition in transportation as we increasingly recognize the dangers of carbon emissions that cause climate change. More and more people today can buy a car powered by lithium-ion batteries as the engineering continues to improve and prices decrease.

Transportation, however, is only one example where lithium-ion batteries now play a key role in how we power our technologies. From automotive systems to drones, and cell phones to toothbrushes to laptops, these batteries are what make them go.

In each application area, the requirements for power, lifetime, safety, and cycling may vary dramatically, meaning that the battery designer must simultaneously take into account several factors when developing a new power system. Because of this complexity, simulation and modelling can play a key role in reducing the time and cost of research and development.

Lithium-Ion Battery Development

Lithium-ion batteries are so useful in modern technologies because this process of charging and discharging may be repeated many times – often thousands of cycles. One key area of ongoing research into lithium-ion batteries focuses on finding ways to reduce aging and degradation of the batteries that inevitably occurs after a large amount of cycling. This centers around finding better ways of constructing the battery structures, improving thermal management, optimizing operational procedures, or developing new materials (the elemental composition of the cathode materials are clearly complicated!).

These facets of battery research apply not only to the aging problem, but to a wide number of questions related to battery design: efficiency, power, size, weight, and cost. All of these factors must be simultaneously considered when developing a new battery for the consumer market, and they are one reason why there is still so much more to learn and to improve.

Modelling Batteries with COMSOL Multiphysics

Batteries are very complex electrochemical systems. How well – or even if – a battery functions depends on the answers to a number of questions, including but not limited to:

- How is charge transported in the electrodes and electrolytes?

- How much heat is generated, and how does it affect electrochemistry?

- Can heat caused by reactions be effectively removed from the battery?

- How should one describe the electrochemical kinetics, which depends on electrode materials, electrode structure (porous or solid), dissolved ions, temperature, ion concentration?

- How do the battery materials physically age after repeated cycling, and how does that affect electronic performance?

- Is the manufacturing process reliable and cost-effective?

Effective battery development relies on a lot of experience, a good understanding of the underlying physics, and a lot of testing. Testing can become very expensive, both in terms of time as well as cost, if not well-focused by experienced scientists and engineers. This is where simulation can help out. While it can’t fully replace the test lab, finite element modelling can be used to focus research programs, highlight auspicious development paths, and rapidly provide information on variations to existing systems; all without the hassle of setting up new lab stations, purchasing materials, manufacturing, and running new physical tests… for each and every possible design variation! Therefore, with the computational resources that are now available, from high powered desktop workstations to cloud computing platforms, simulation has become an indispensable tool for advancing systems with ever greater complexity.

Digital Twins for Battery Design

A Digital Twin is a model, or more often, a set of models, which can be used describe different kinds of processes in a system in real-time (or near real-time), utilizing both measured data from a physical device along with finite element modelling. Using parameter estimation, Digital Twins can help engineers understand how the device behaves on different size and time scales, and to assess engineering trade-offs when input parameters are varied.

Battery design is one area that makes great use of this approach, because ultimately the behaviour of a battery system depends on complex, simultaneous interactions of multiple factors. Some of these include, for example:

- Ionic transport in electrolytes or within solid electrode materials

- Electronic conductivity

- Heat generation and transport

- Composition, shape and size of microscopic electrode particles

- Electrode geometry

- Electrolyte composition

- Operating currents and voltages

- Battery-pack layout.

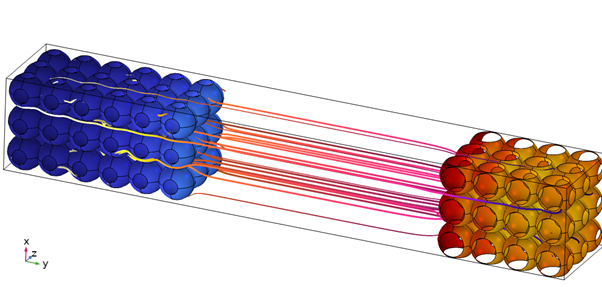

Exchange current density at the surfaces of anode (left) and cathode (right) particles, with streamlines showing ionic current in the electrolyte.

These considerations span orders of magnitude with respect to complexity, size, and time-scale, presenting a formidable engineering challenge.

Sub-models representing facets of the system may include highly resolved local processes, such as transport and diffusion of lithium ions at individual electrode particles, or they may represent lumped quantities, which are described using homogenized domains and effective material properties.

High-resolution models are often built in 3D and require fine meshing, leading to a large number of degrees of freedom to solve for, and thus long computational times.

How Xi Can Help

Xi Engineering Consultants can accelerate research and development, explore and assess new concepts with significantly reduced cost for materials, and test your design. We can help you understand how the device behaves at different sizes and time scales, and to assess engineering trade-offs when input parameters are varied. Xi works with companies of all sizes, every project is different, and we tailor our approach to fit your needs: whether that means focusing on an individual aspect of your project, resolving unforeseen issues, or providing holistic support across your entire development journey. Get in touch with our team to talk about your project.