With the ever-increasing demand for small and precise technology and equipment for both consumer and scientific use (such as nanotechnology), there is a growing need for clean rooms and laboratories to house and manufacture these micro-technologies. In this blog post, Xi considers the importance of mitigating against building vibrations in clean room and laboratory design.

Building Vibration Control for clean rooms and sensitive equipment

Having dealt with vibrations in buildings for over a decade, our team has come across two general problems.

- large scale vibration caused by local sources such as piling or railway lines which can damage buildings and influence the human inhabitants of these structures.

- Buildings which house sensitive equipment such as semiconductor equipment, microscopes and lasers which require very low vibration levels for the machines to function correctly.

The only difference between these two vibration-related concerns is that of scale or level of vibrations. In this blog post we focus on sensitive equipment. To find out more information about vibrations in larger-scale buildings and structures visit our Building, structures & planning webpage.

What is nanotechnology?

Nanotechnology is defined as a branch of technology that deals with dimensions and tolerances less than 100nm. As technology is progressing, we are continuously pushing boundaries and trying to create smaller and smaller objects. Following Moore’s law, manufacturing of computer chips is producing transistors (the building blocks of computer chips) in large volumes around the 5nm scale, and sub 1nm for smaller runs. Advanced transmission electron microscopes (TEM’s) have a limit of resolution of below 1nm.

How small is a Nanometer?

A nanometer is a billionth of a meter. A hair on your head is approximately 75,000 nanometers. A human red blood cell is 6,000 -8,000nm in diameter. Machines which work on this scale need to be stable to achieve these precise levels. Drawing straight lines on a piece of paper is impossible if your hand is being shaken. Think of writing in a car or bus. Semiconductor manufacturing equipment is the same. Machines cannot draw lines into silicon if they are being shaken around.

Building vibration assessments

When assessing a semiconductor facility or a building to house sensitive equipment like lasers or microscopes it is crucial to assess the floor vibration in respect of these criterion curves. Local vibration sources like roads, large machines, lifts, and HVAC equipment all contribute to the levels experienced in a building. The actual sway of the building will also be a contributing factor once you get down to some of the more stringent criteria. Housing laboratories in upper floors will increase the levels of vibration experienced and it is always better the lower you go. Ground floors are ideal, however, basements are even better, as the effects of wind on a structure are less pronounced than on upper floors.

Vibration assessments for laboratories & clean rooms

We have found it to be rare that laboratories are housed at ground level. The ground level is usually reserved for communal space, reception areas and meeting spaces. As this is the case vibration should be considered carefully during the early stages of designing a building. The likely use of laboratories and what equipment is to be housed within it will need to be determined early in the design. Care should be taken when assessing manufacturers data sheets and even contractual arrangement. Manufacturers may include passing building vibration specifications as necessary criteria in granting their warranty. Xi has, in fact, helped a client and a manufacturer overcome exactly this barrier to the sign off of a £9M laser, by identifying and resolving the building vibration in the structure housing the equipment. If you are considering Laboratory or Clean Room design, we would highly recommend that you get in touch with a member of our team for vibration measurement and assessment.

Environmental Vibration Criteria Curves

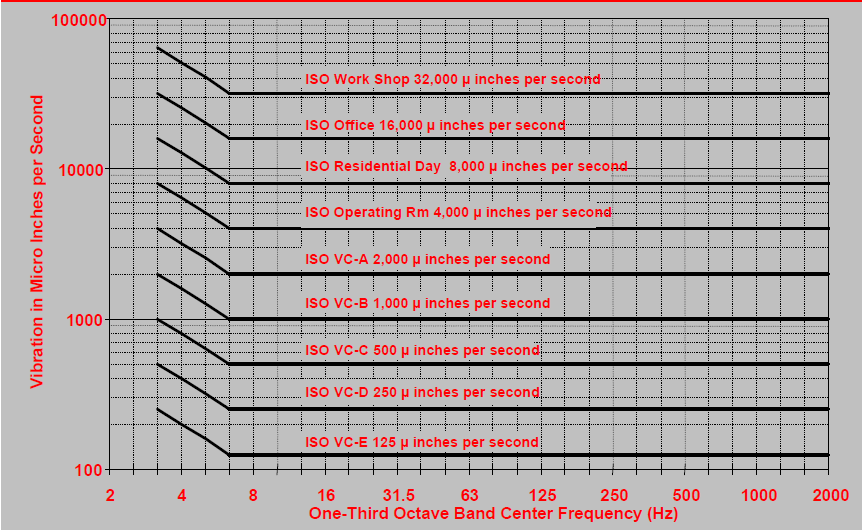

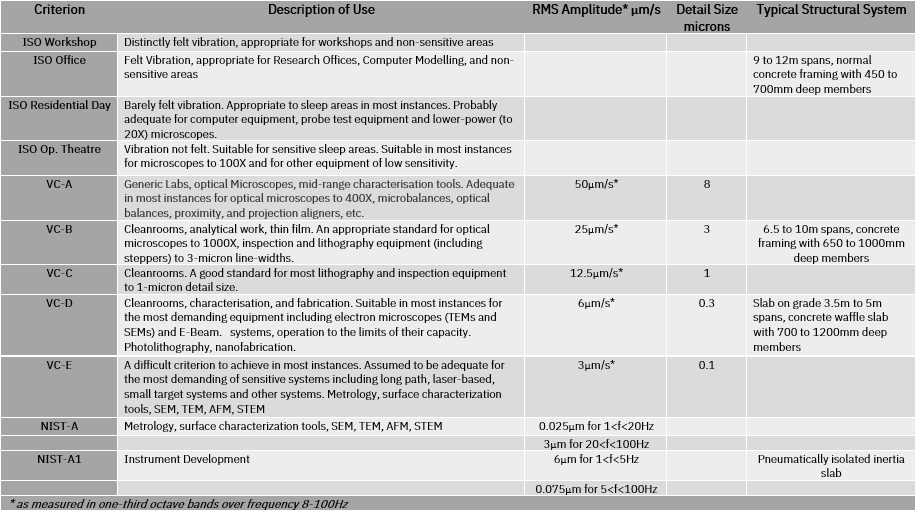

Generic Criterion Vibration curves have been developed over the years based on measurements in semiconductor fabrication facilities and have been used by Xi and leading vibration consultants within the industry for decades. These curves have evolved with the evolution of ever more accurate scientific machines and smaller technology.

Figure 1: Generic Vibration Criterion Curves. Ashrae recommended vibration criteria, Neil Moiseev, Associate Principal Cerami & Associates, Inc, New York.

Figure 1 shows the vibration criterion curves for RMS (Root Mean Square) Vibration velocity levels vs frequency. Any laboratory or room housing sensitive equipment needs to be below the appropriate curve for the equipment to be used in a facility. Table 1 provides descriptions of each of these curves along with what machinery is appropriate. Furthermore, it provides a guide to the likely structural make-up of the floor required.

How are the Vibration Criterion Curves being used?

Vibration Criterion Curves are used as indicative levels and are generally conservative. This is the starting point of any vibration assessment which provides an understanding of how problematic vibrations are likely to be. It should be noted that a comprehensive study is likely to look at both narrowband spectra as well as the criterion levels. As is so often the case; the devil is in the detail, and vibrations are no exception to this rule. As these levels are route mean square (RMS) over frequency bands, specific problem frequencies are not always obvious. Resonances within floors can be extremely problematic if they are close to an operating frequency of a machine. If you think of the millennium bridge as a laboratory floor and the people walking on it as a machine, the impact of frequency matching with a resonance has on the overall vibration levels is vast.

International Standards Organisation (ISO) levels for large scale vibrations

Large scale vibration levels can be seen in the higher curves as defined by the International Standards Organisation (ISO) levels. Members of the Xi team sit on committees which directly look at these higher-level vibration exposures and review and update these ISO standards directly.

Deal with vibrations as early as possible

The earlier you deal with vibrations the more efficient and cost-effective the solution can be. Dealing with vibration late in the design and construction phase can lead to costly delays and commercial difficulties. If you are building, converting or upgrading a cleanroom or laboratory for sensitive equipment please consider vibrations. In the nanoworld in which we now live vibrations are increasingly becoming more problematic to meet the demands of highly accurate technology.

Why choose Xi Engineering

Our extensive experience in building and structural dynamics allows us to support your team in dealing with complex issues across both commercial and technical markets. Xi’s measurement team and specialist equipment combined with our powerful simulation tools will help to validate models and potential designs with real world observations. Our engineers can help you to complete your project in a manner which is fit for purpose, compliant with relevant legislation and efficient in terms of time and resources.